From the Field to the Dashboard – Built by Experts, for Experts.

Discover What's Really Happening in the Steel Industry

Use the AI-powered search engine to analyze production activity, market trends, and news faster than ever before.

Try the Free AI Search EngineSweden’s Green Steel Revolution: SSAB’s Fossil-Free Mill and Stegra’s Microsoft Deal Drive Positive Market Sentiment

Sweden’s steel market is experiencing a period of positive transformation, fueled by advancements in green steel production. The commencement of construction at SSAB’s fossil-free steel mill in Luleå, as reported in “Construction begins on SSAB’s fossil-free steel mill in Sweden” and “Groundbreaking at fossil-free mini-mill in Sweden“, signal significant capacity expansion. Simultaneously, Stegra’s agreement to supply Microsoft with near-zero emission steel, as detailed in “Sweden’s Stegra to supply Microsoft with green steel from Boden plant“, demonstrates increasing demand for sustainable steel.

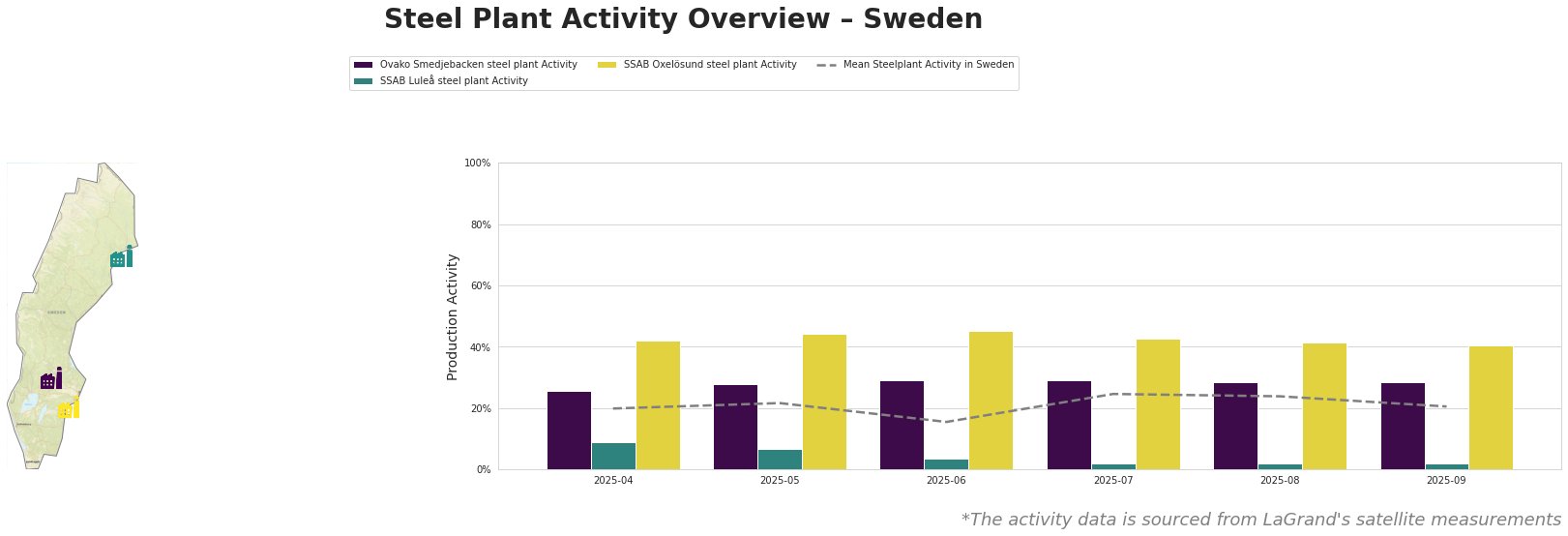

Here’s a summary of recent steel plant activity:

The mean steel plant activity in Sweden fluctuated between 16% and 25% over the observed period, ending at 21% in September. Ovako Smedjebacken’s activity remained relatively stable, hovering around 28-29%. SSAB Luleå experienced the lowest activity levels, consistently below 10%, while SSAB Oxelösund displayed the highest activity, ranging from 40% to 45%.

Ovako Smedjebacken steel plant: This plant in Dalarna, with a capacity of 1.01 million tonnes per annum (ttpa) of crude steel produced via electric arc furnaces (EAF), focuses on finished rolled products like high wear resistance steel and spring steel for the automotive, energy, and machinery sectors. The plant’s activity remained relatively stable at around 28-29% throughout the period, showing no significant impact directly linked to the provided news articles.

SSAB Luleå steel plant: Situated in Norrbotten, this integrated steel plant relies on blast furnace (BF) and basic oxygen furnace (BOF) processes, boasting a crude steel capacity of 2.3 ttpa and an iron capacity of 2.555 ttpa. Activity at the SSAB Luleå plant remained consistently low, at 2% in September, significantly below the mean. While “Construction begins on SSAB’s fossil-free steel mill in Sweden” and “Groundbreaking at fossil-free mini-mill in Sweden” detail the construction of a new fossil-free mill in Luleå, these activities are separate from the existing BF/BOF operations and do not appear to be directly affecting the observed activity levels at the current plant.

SSAB Oxelösund steel plant: Located in Södermanland, this integrated plant, also using BF and BOF technology, has a crude steel capacity of 1.5 ttpa and an iron capacity of 1.55 ttpa. It specializes in high-strength and wear-resistant steel products like Hardox and Strenx. The plant consistently showed high activity, ending at 40% in September. There is no apparent correlation between its performance and the provided news items about SSAB Luleå or Stegra.

Evaluated Market Implications:

The construction of SSAB’s fossil-free mill in Luleå, combined with Stegra’s green steel supply agreement, indicates a structural shift towards sustainable steel production in Sweden. Despite construction beginning, the old plant must still meet the demand. Given SSAB Luleå’s consistently low observed activity (2% in September), the construction work is not impacting existing operations.

However, the construction of the new SSAB mill suggests that the old one will not operate much longer, leading to supply disruptions in the medium-term during the transition phase and ramp-up of the new plant.

Recommended Procurement Actions:

Steel buyers should closely monitor SSAB Luleå’s production output and prepare for potential supply shortages related to conventional steel grades as SSAB transitions to fossil-free production. Diversifying suppliers and exploring green steel alternatives, particularly from Stegra, may be prudent strategies to mitigate risks. Analysts should closely track the commissioning and ramp-up of the new SSAB mill in Luleå to assess its impact on the overall steel supply chain.