From the Field to the Dashboard – Built by Experts, for Experts.

Discover What's Really Happening in the Steel Industry

Use the AI-powered search engine to analyze production activity, market trends, and news faster than ever before.

Try the Free AI Search EngineSignificant Decline in Activity at North Korean Steel Plant Raises Supply Concerns

Introduction

The Kim Chaek Iron and Steel Complex steel plant, located in North Hamgyeong, North Korea, is a state-owned facility with an annual production capacity of 6,000 tons of crude steel. It specializes in producing semi-finished and finished rolled steel products serving sectors like tools and machinery.

Activity Changes Over Time

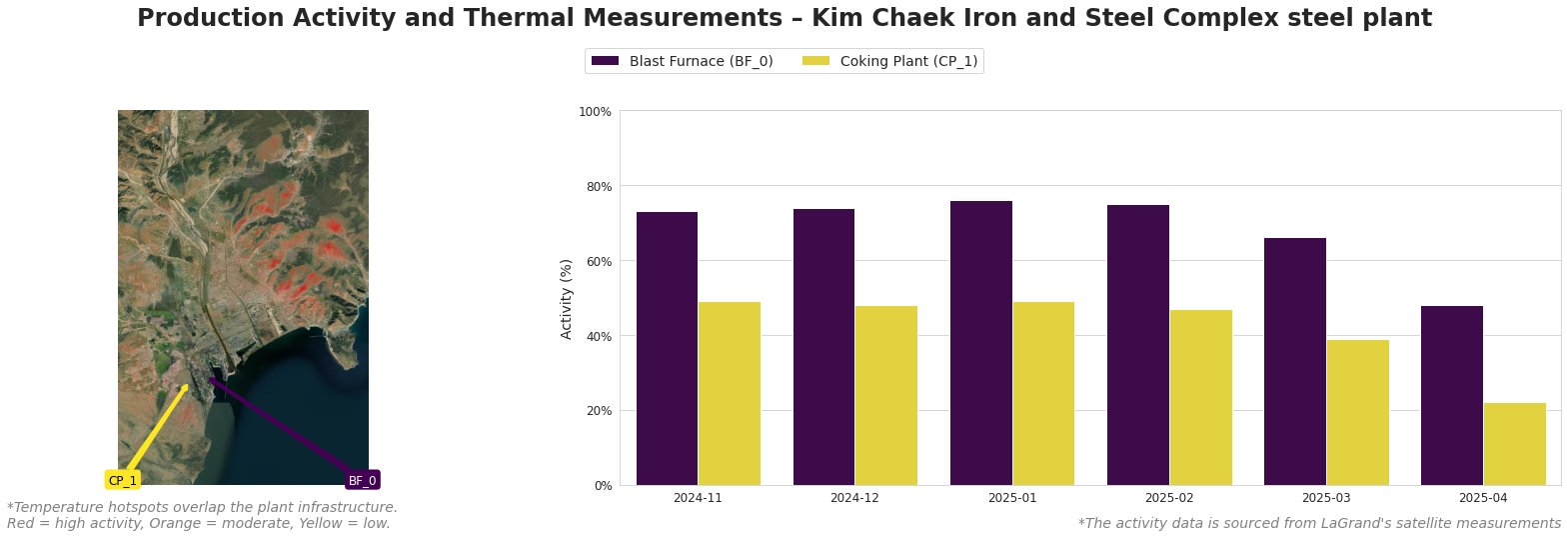

Recent satellite-based observations indicate a troubling decline in operational activity at the complex. The table below outlines the thermal activity of key equipment over recent months:

The thermal activity of the Blast Furnace has seen a notable decline, with a drop from 66% in March to 48% in April. The Coking Plant, too, has faced decreased operational levels, plummeting to 22% in April. This overall activity change amounts to a significant decline of 29.07%, signaling a red alert status that may indicate broader operational instability.

Implications for Steel Buyers and Market Analysts

The drastic reduction in activity at the Kim Chaek plant raises concerns about potential supply shortages in the market. As suppliers confront decreasing output, the risk of operational bottlenecks increases, impacting the availability of semi-finished and finished steel products. This development comes amidst varying trends globally; while China is increasing production, as noted in the article China increases steel production to 10-month high in March, a decline in North Korean steel output could lead to elevated prices and strained availability in the regional market. Buyers need to consider these dynamics as they plan future procurements, especially given the potential for rising demand and production cuts from other markets as discussed in Chinese steel giant urges to avoid strict production controls.