From the Field to the Dashboard – Built by Experts, for Experts.

Discover What's Really Happening in the Steel Industry

Use the AI-powered search engine to analyze production activity, market trends, and news faster than ever before.

Try the Free AI Search EnginePositive Market Momentum: Steel Plant Activity in Asia Shows Encouraging Trends

Recent activity levels among Asia’s steel plants reflect a notably positive market sentiment, driven by multiple influencing factors. In particular, the article titled “No upstream gain from US’ Venezuela intervention“ highlights geopolitical dynamics that have the potential to impact global oil supplies, subsequently influencing steel production costs and materials accessibility. However, direct connections to recent activity changes in steel plants remain ambiguous.

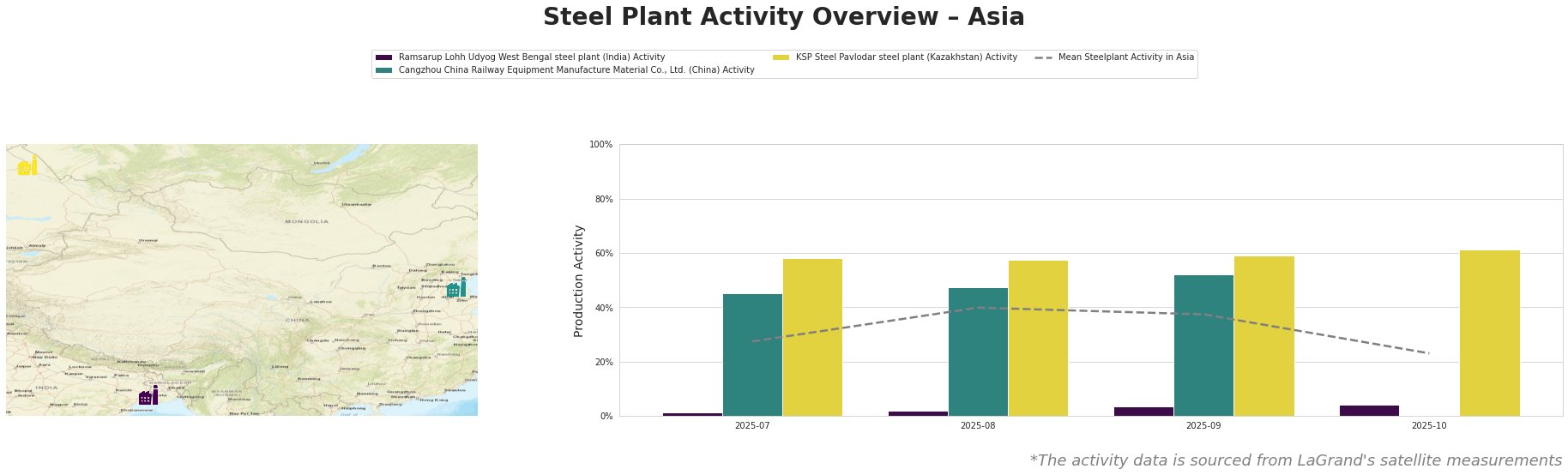

The Ramsarup Lohh Udyog West Bengal steel plant in India has experienced a gradual increase from 1.0% in July to 4.0% by October, reflecting the lowest overall activity compared to its peers. Despite this rise, it pales in comparison to the mean activity level of 27.0%, suggesting challenges in scaling production effectively. The plant’s integrated processes support various finished and semi-finished products, primarily serving the energy sector, but remain constrained at low operational outputs with no clear source of growth indicated by recent news.

Cangzhou China Railway Equipment Manufacture Material Co., Ltd. operates at a much higher activity level but showed slight fluctuations, moving from 45.0% to a peak of 52.0%. This aligns with stable demand from the tools and machinery and transport sectors. However, recent news indicates that potential geopolitical disruptions may affect market dynamics going forward, although a direct correlation with activity shifts is not firmly established.

KSP Steel Pavlodar in Kazakhstan exhibited the most significant operational resilience, starting from 58.0% and enhancing up to 61.0%. Its advanced electric arc furnace processes allow it to produce a diverse range of finished and semi-finished products, targeting sectors like energy and machinery. This performance strongly suggests that opportunities for procurement exist, particularly as geopolitical instability fuels demand in various applications.

Considering these trends, steel buyers should cautiously evaluate sourcing strategies from the KSP Steel Pavlodar plant, as it shows promising activity levels and product diversification. Careful monitoring of geopolitical developments featured in the article titled “US details plans to take over PdV sales: Update,” is advised, given their potential to impact raw material costs and supply chain stability. The increased stability in the Pavlodar plant, combined with a robust product offering, may yield beneficial procurement avenues.