From the Field to the Dashboard – Built by Experts, for Experts.

Discover What's Really Happening in the Steel Industry

Use the AI-powered search engine to analyze production activity, market trends, and news faster than ever before.

Try the Free AI Search EngineDeclining Activity at Nucor Plant Raises Concerns Amid Fluctuating Steel Prices

Introduction

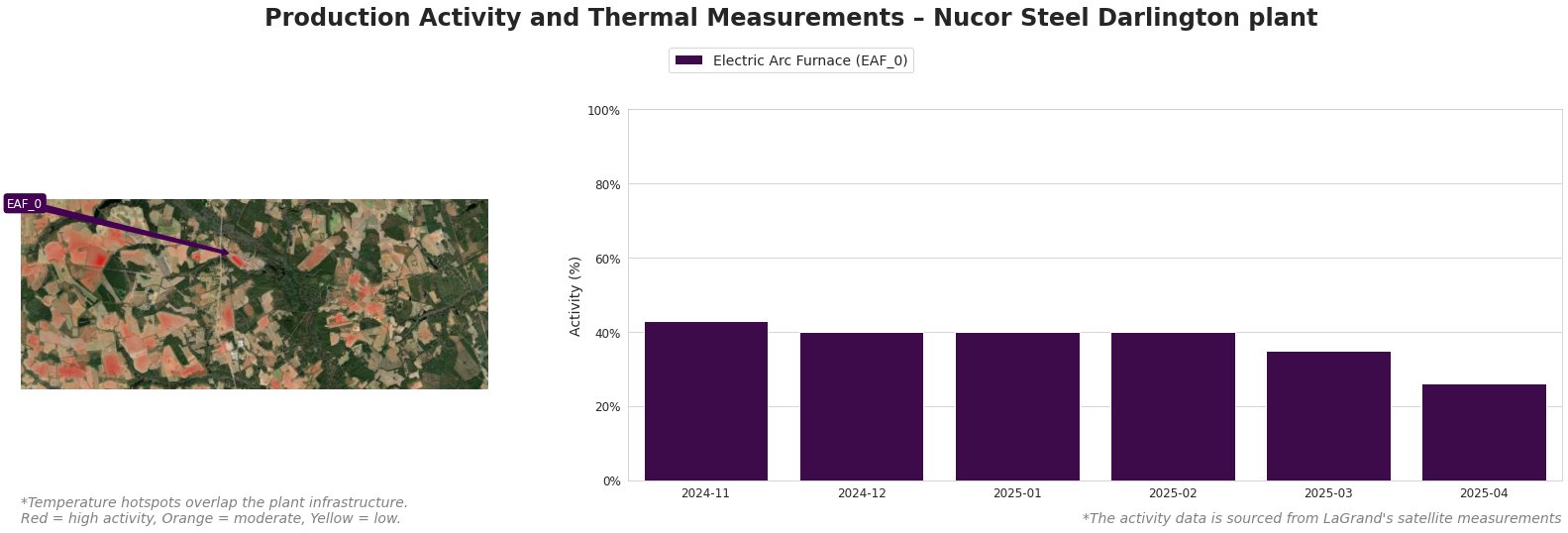

The Nucor Steel Darlington plant, located in South Carolina, operates under Nucor Corporation, specializing in electric arc furnace (EAF) production with an annual capacity of 907,000 tons. Its main products include finished rolled steel products like bars and engineered bars, serving critical end-user sectors such as automotive, building and infrastructure, and energy.

Activity Change Over Time

Recent satellite observations indicate that the thermal activity of the Electric Arc Furnace (EAF_1) at the Nucor Steel Darlington plant has significantly decreased, revealing a downward trend in operational capacity.

This data shows a decline from 43% in late November 2024 to 26% by the end of April 2025, signifying a consistent drop in operational levels. Such reductions raise eyebrows as Nucor has recently adjusted prices for hot rolled coils, suggesting fluctuations in both supply and demand dynamics in the market.

Implications for Steel Buyers and Market Analysts

The declining trend in thermal activity, coupled with Nucor’s recent price cuts for hot rolled coils as noted in Nucor cuts prices for hot rolled coils for the first time since the beginning of the year, may suggest an oversupply or weakening demand within certain market segments. This could potentially lead to supply chain bottlenecks if production levels do not stabilize or improve.

Moreover, pressures from global trade disruptions affecting demand growth, as highlighted in ArcelorMittal: Trade disruptions threaten projected demand growth, underline the volatility of market conditions that steel buyers and analysts must consider. As competition heats up, understanding these operational changes at the Nucor plant will be vital in navigating pricing strategies and supply forecasts in the coming months.