From the Field to the Dashboard – Built by Experts, for Experts.

Discover What's Really Happening in the Steel Industry

Use the AI-powered search engine to analyze production activity, market trends, and news faster than ever before.

Try the Free AI Search EngineAustria’s Steel Market Thrives: Planned Upgrades at Voestalpine Warm Up Production Sentiment

Austria’s steel industry is currently experiencing a Very Positive market sentiment, primarily driven by significant operational upgrades underway at key facilities. The recent article “Primetals upgrades pickling and tandem mill at voestalpine“ directly correlates with observed enhancements in the activity levels at the Voestalpine Stahl Linz plant, anticipated to elevate production capacity for high-strength steels used in automotive and construction sectors.

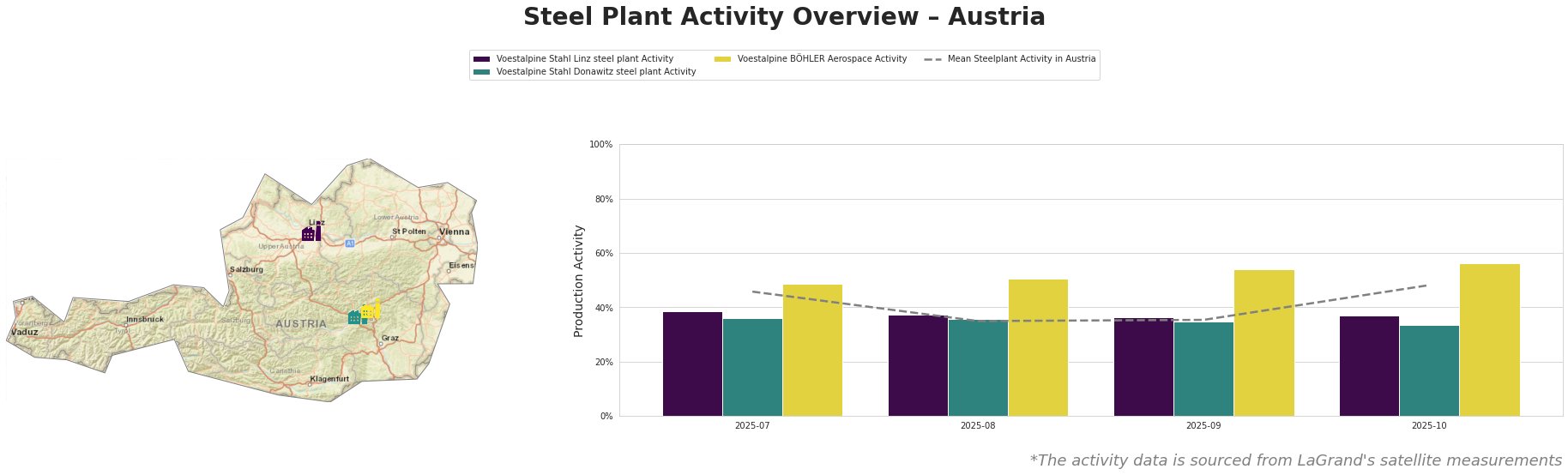

The data showcases a concerning drop in mean activity levels across all steelplants, with the Linz facility peaking at 38.0% in July and then experiencing a downturn in August and September (37.0% and 36.0%, respectively). In October, a significant uptick in overall activity to 48.0%, driven by BÖHLER Aerospace and its rise to 56.0%, may indicate recovery momentum. However, the activity at Voestalpine’s Donawitz plant has remained relatively stable, slightly declining from 36.0% in July to 34.0% in October.

The Voestalpine Stahl Linz plant operates using an integrated blast furnace (BF) process and boasts a production capacity of 6000 tons of crude steel. The effects of the upgrade mentioned in “Voestalpine tasks Primetals with automation upgrade“ are expected to provide long-term benefits by enhancing system reliability for high-strength and ultra-high-strength steel production, particularly as it aligns with broader market demands in automotive applications.

Conversely, the Donawitz plant has not shown connections to any recent upgrades, as indicated by stagnant activity levels, which could be a red flag for procurement professionals monitoring supply consistencies. Meanwhile, BÖHLER Aerospace, engaged mainly in electric arc furnace processes, continues to experience positive growth, implying a shift towards more specialty steel production that could attract buyers seeking innovation within aerospace engineering sectors.

Clear procurement recommendations include focusing sourcing strategies around Voestalpine’s Linz facility post-upgrade, ensuring long-term contract negotiations that guarantee access to high-strength steel. Additionally, buyers should remain vigilant of potential supply disruptions from the Donawitz plant, amid its unchanged operational state.

In summary, Austria’s steel landscape is brimming with potential as significant automation upgrades enhance production capabilities, suggesting a strong foundation for future procurement strategies tailored to meet evolving market needs.