From the Field to the Dashboard – Built by Experts, for Experts.

Discover What's Really Happening in the Steel Industry

Use the AI-powered search engine to analyze production activity, market trends, and news faster than ever before.

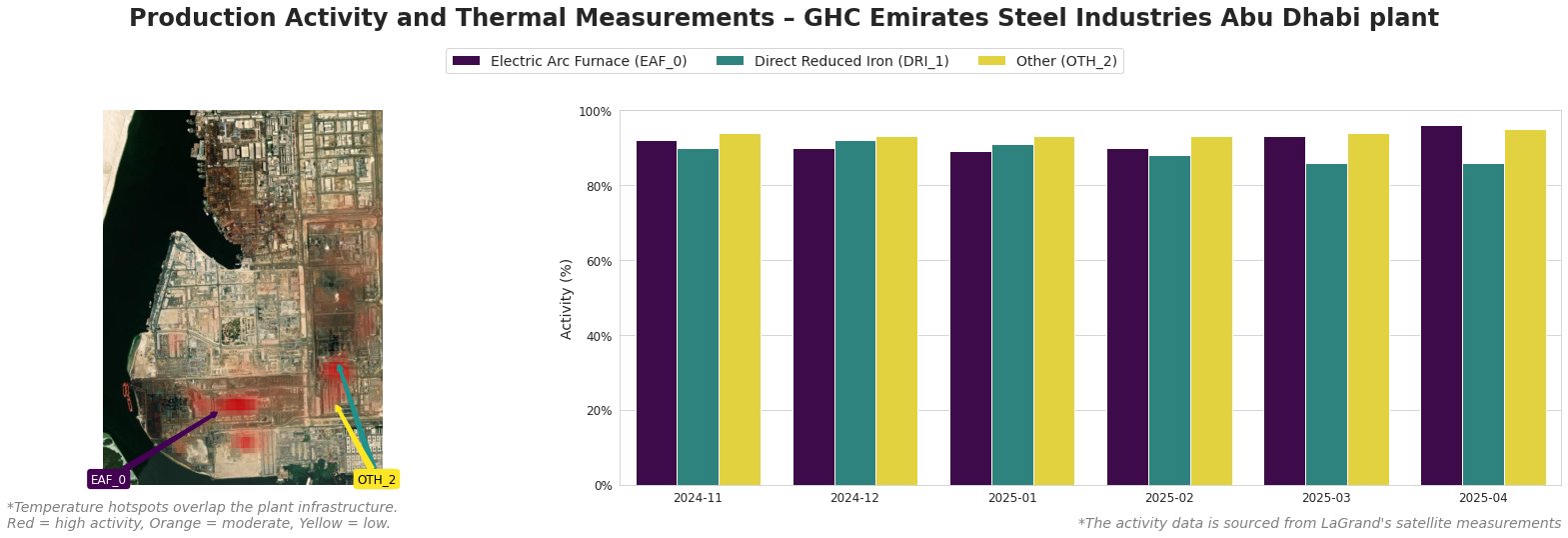

Try the Free AI Search EngineRising Thermal Activity at GHC Emirates Steel Reflects Strong Market Demand

Introduction

GHC Emirates Steel Industries, located in Abu Dhabi, United Arab Emirates, has reached an annual production capacity of 3.5 million tons while producing key steel products such as rebar, wire rod, and heavy sections. As a significant player in the regional steel market, serving sectors like automotive, building and infrastructure, and energy, the plant is owned by Emirates Steel and is critical to the UAE’s manufacturing landscape.

Activity Trends Over Time

Recent observations indicate a noticeable increase in thermal activity at the plant, with a total activity change of +7.45%. This change underscores a positive market trend for steel production, particularly highlighted by the following equipment performance:

The Electric Arc Furnace exhibited a peak of 96% operational activity in April 2025, reflecting a strong response to market demands. Although the Direct Reduced Iron showed some variation, its overall performance indicates stability, supporting the increased output from the EAF.

Implications for Steel Buyers and Market Analysts

The upward trend in activity levels suggests that steel supply is responding favorably to heightened market demands, potentially alleviating concerns about inventory shortages. Given Emsteel’s recent push towards sustainable steel production, as noted in UAE: Emsteel Leads Regional Sustainable Steel Production Efforts, buyers can anticipate more environmentally responsible products entering the supply chain. Moreover, investment in innovation and sustainability, evidenced by Emsteel increased spending on innovation and investment by 127% in 2020-2024, might enhance operational efficiencies and reduce costs in the long term.

The operational stability demonstrated through consistent thermal activity bodes well for future supply stability, but market analysts should remain vigilant regarding external factors that could influence production and pricing. The ongoing regional push for decarbonized steel manufacturing could redefine competitive dynamics in the steel industry.