From the Field to the Dashboard – Built by Experts, for Experts.

Discover What's Really Happening in the Steel Industry

Use the AI-powered search engine to analyze production activity, market trends, and news faster than ever before.

Try the Free AI Search EngineDeclining Activity at İDÇ Izdemir Aliaga Plant Signals Potential Supply Challenges

Introduction

Located in İzmır, Türkiye, the İDÇ Izdemir Aliaga steel plant produces a variety of steel products, including deformed bars and H beams, with an annual capacity of 1,400,000 tonnes. Owned by İDÇ, this facility plays a crucial role in supplying the construction and manufacturing sectors, emphasizing the importance of its operational health amid a fluctuating market landscape.

Activity Changes Over Time

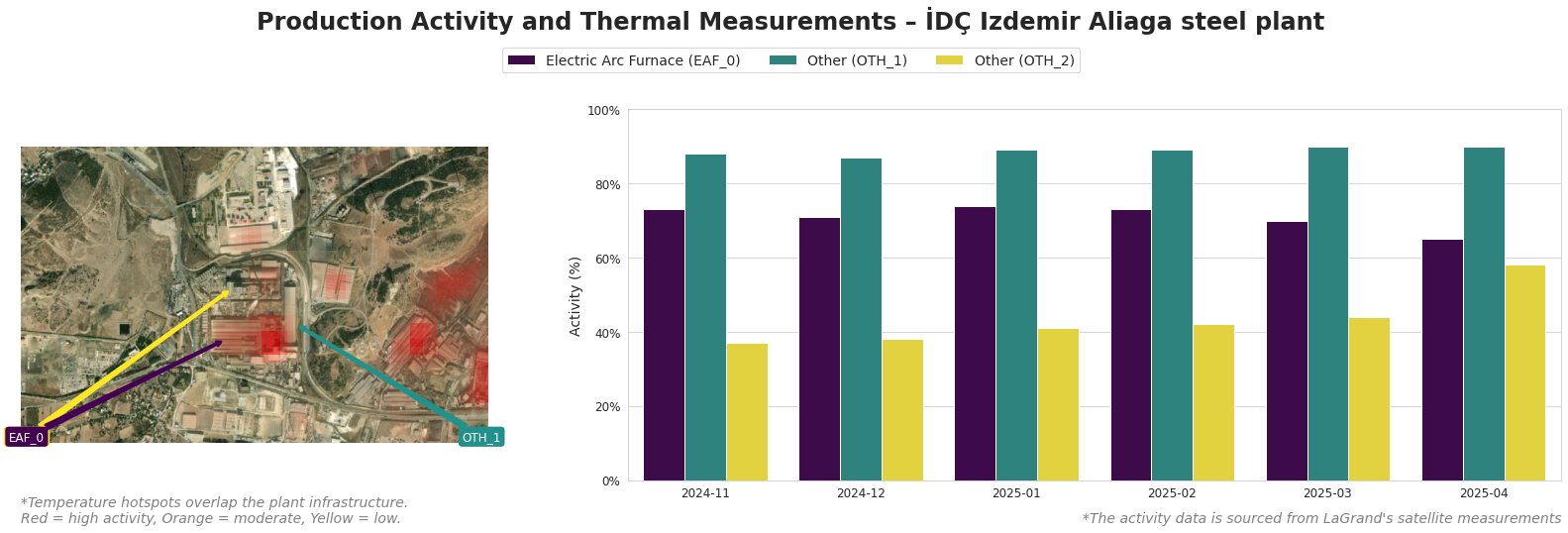

Recent satellite observations reveal a notable decline in operational activity at the İDÇ Izdemir Aliaga plant. The Electric Arc Furnace (EAF) has exhibited significant decreases in thermal activity, signaling potential production constraints.

Over the past five months, the EAF’s activity has dropped from 73.0% to 65.0%, aligning with wider market trends where Turkish steel production saw a 7% month-on-month increase in March 2025, but still faced overall year-on-year declines (Turkey increased steel production by 7% m/m in March). The recent reductions at İDÇ contrast sharply with this national trend, suggesting operational challenges that could impact supply reliability.

Implications for Steel Buyers and Market Analysts

The observed decrease in activity at the İDÇ Izdemir Aliaga plant indicates potential supply constraints, particularly amidst a backdrop of rising national production. For steel buyers and market analysts, this could signify upcoming bottlenecks or increased pressure on supply chains, especially as reported by various sources on production dynamics in Turkey. Additionally, any disruptions in output at this plant may limit availability in the local market, potentially affecting pricing and inventory levels.

This decline highlights the importance of closely monitoring thermal activity trends, as they can be indicative of broader market movements influenced by international competition, ongoing demand shifts, and geopolitical factors affecting commodity prices.