From the Field to the Dashboard – Built by Experts, for Experts.

Discover What's Really Happening in the Steel Industry

Use the AI-powered search engine to analyze production activity, market trends, and news faster than ever before.

Try the Free AI Search EngineFrench Steel Market Alert: Fos-sur-Mer Fire Disrupts Supply Amidst Stable Activity

France’s steel market faces potential disruption following a fire at ArcelorMittal’s Fos-sur-Mer plant. Three articles, “ArcelorMittal Fos-sur-Mer shut down blast furnace No. 2 due to a fire“, “ArcelorMittal Shuts Down Fos-sur-Mer Blast Furnace After Major Fire“, and “ArcelorMittal shuts down Fos-sur-Mer blast furnace after major fire incident” directly correlate with concerns about immediate supply chain impacts, given the plant’s role in slab production. The news reports confirm the blast furnace was shut down on October 8, 2025, and a disruption of downstream production due to a dependency on the blast furnace. Satellite data from October 2025 does not yet reflect this event, as the observation represents the monthly average activity.

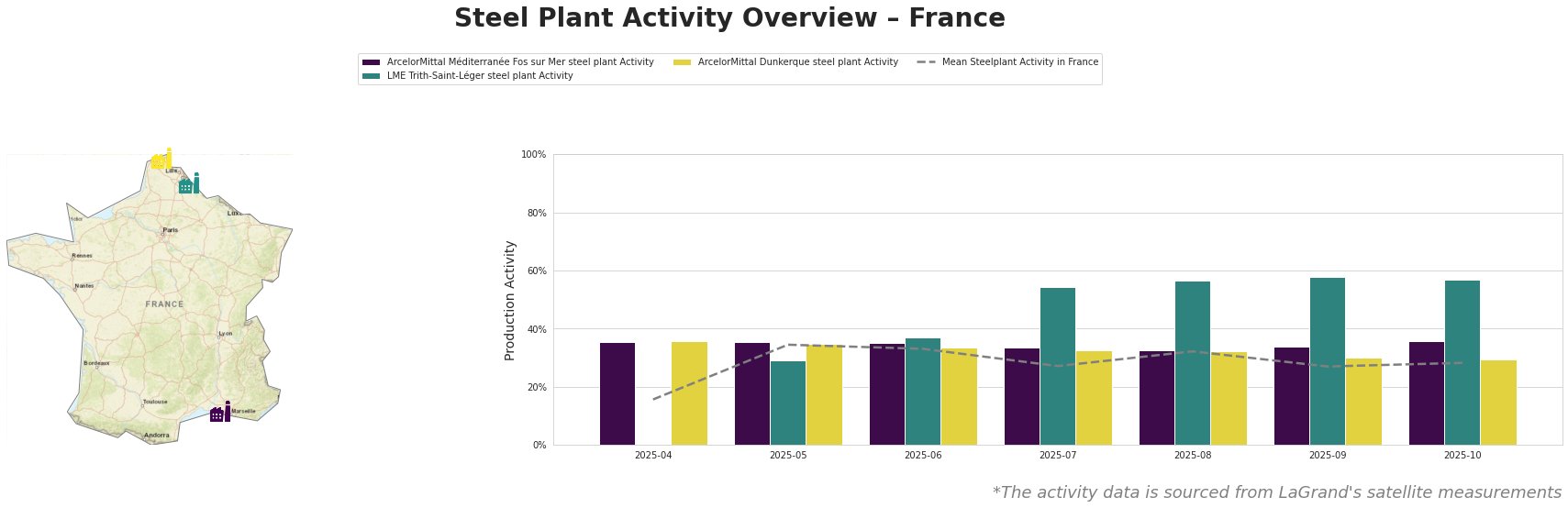

Over the observed period, average steel plant activity in France fluctuated, starting at 16% in April and reaching 34% in May, before stabilizing around 27-33% for the remaining months. ArcelorMittal Méditerranée Fos-sur-Mer plant activity remained consistently high, ranging from 33% to 36%. LME Trith-Saint-Léger demonstrated the highest activity levels, peaking at 58% in September. ArcelorMittal Dunkerque exhibited relatively stable activity, hovering between 29% and 36%. The satellite data for October does not yet reflect the impact of the fire at Fos-sur-Mer, which occurred on October 8th.

ArcelorMittal Méditerranée Fos-sur-Mer, located in Provence-Alpes-Côte d’Azur, is a large integrated steel plant with a crude steel capacity of 4 million tonnes per annum (ttpa) using basic oxygen furnace (BOF) technology. The plant, equipped with a blast furnace (BF), produces slabs, hot-rolled products, and coils for various sectors, including automotive and construction. Activity remained consistent between 33% and 36% from July to October, preceeding the plant shut down. The news reports, “ArcelorMittal Fos-sur-Mer shut down blast furnace No. 2 due to a fire“, “ArcelorMittal Shuts Down Fos-sur-Mer Blast Furnace After Major Fire“, and “ArcelorMittal shuts down Fos-sur-Mer blast furnace after major fire incident“, indicate the shutdown of Blast Furnace No. 2, which is likely to lead to a decrease in plant activity in subsequent months and a significant impact on slab supply.

LME Trith-Saint-Léger, situated in Hauts-de-France, operates an electric arc furnace (EAF) with a crude steel capacity of 850,000 ttpa, producing slabs, hot-rolled products, and coils. Its activity levels were noticeably higher than the national average, consistently ranging from 54% to 58% from July to October. No direct connection can be established between LME Trith-Saint-Léger activity levels and the news articles provided.

ArcelorMittal Dunkerque, also located in Haus-de-France, is an integrated steel plant using BOF technology, boasting a crude steel capacity of 6.75 million ttpa. Similar to Fos-sur-Mer, it relies on a blast furnace (BF). The plant’s activity has been relatively stable, fluctuating between 29% and 36% from April to October. No direct connection can be established between ArcelorMittal Dunkerque activity levels and the news articles provided.

The fire at ArcelorMittal Fos-sur-Mer, as reported in “ArcelorMittal Fos-sur-Mer shut down blast furnace No. 2 due to a fire“, “ArcelorMittal Shuts Down Fos-sur-Mer Blast Furnace After Major Fire“, and “ArcelorMittal shuts down Fos-sur-Mer blast furnace after major fire incident“, presents a potential supply disruption for slabs, particularly impacting the automotive, building, and energy sectors that rely on the plant’s output. Given the plant’s essential role in supplying slabs, steel buyers should immediately:

- Assess Slab Inventory: Evaluate current slab stock levels and project consumption rates to determine potential shortfalls resulting from the Fos-sur-Mer shutdown.

- Contact ArcelorMittal: Directly engage with ArcelorMittal to understand the extent of the damage, the expected duration of the shutdown, and potential alternative sourcing options.

- Explore Alternative Suppliers: Proactively identify and qualify alternative slab suppliers, focusing on those in Europe or other regions that can readily supply the required specifications and quantities. Consider LME Trith-Saint-Léger as a potential alternative source.

- Negotiate Contractual Terms: Review existing contracts with ArcelorMittal and other suppliers to understand force majeure clauses and potential price adjustments due to supply disruptions.