From the Field to the Dashboard – Built by Experts, for Experts.

Discover What's Really Happening in the Steel Industry

Use the AI-powered search engine to analyze production activity, market trends, and news faster than ever before.

Try the Free AI Search EngineSweden’s Green Steel Revolution: SSAB Luleå Investment Signals Strong Market Ahead

Sweden’s steel market sentiment is very positive, driven by substantial investments in green steel production. SSAB’s commitment to fossil-free steel is underscored by the commencement of the Luleå green steel mill construction. As highlighted in “Sweden’s SSAB breaks ground for Luleå green steel mill,” “SSAB begins construction of a new plant in Luleå,” “Deputy Prime Minister, SSAB CEO Break Ground on New Steel Mill in Luleå“, and “Construction begins on SSAB’s fossil-free steel mill in Sweden,” this project will significantly impact Sweden’s steel production landscape. These articles detail the shift towards electric arc furnaces, sponge iron, and recycled scrap, signaling a long-term transformation in the industry. While construction is underway, no immediate correlation can be established between these announcements and the recent satellite-observed activity levels, particularly the consistently low activity at the SSAB Luleå plant.

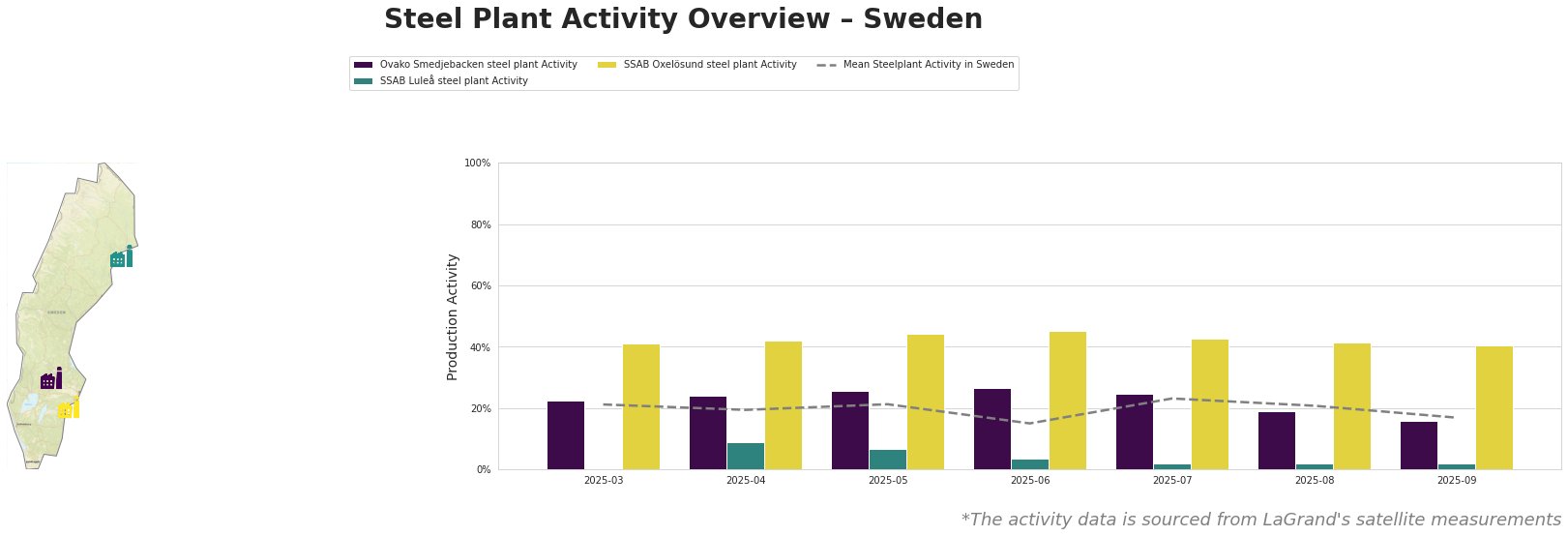

Over the past seven months, the mean steel plant activity in Sweden has fluctuated, reaching a high of 23% in July and a low of 15% in June. Ovako Smedjebacken’s activity peaked at 27% in June, while SSAB Luleå remained consistently low, bottoming out at 2% from July to September. SSAB Oxelösund consistently showed the highest activity levels, ranging from 41% to 45%. The low activity at SSAB Luleå does not seem to be directly correlated with the news articles regarding the new mill, which focuses on long-term construction and future operations.

Ovako Smedjebacken, equipped with three EAFs and boasting a crude steel capacity of 1,010 ttpa, specializes in high wear resistance, spring, and micro-alloyed steels for the automotive, energy, and machinery sectors. The plant holds a ResponsibleSteel Certification, demonstrating a commitment to sustainability. The observed activity fluctuated during the period but was usually above the average for all plants, ending at 16% in September. No direct connection can be established between these activity levels and the news articles provided.

SSAB Luleå, an integrated steel plant with a 2,300 ttpa crude steel capacity using BF and BOF technologies, produces slabs, coke, crude iron, and cast products. While the plant holds ISO14001 and ResponsibleSteel certifications, its activity remained consistently low, at 2% between July and September, and was significantly below the mean Swedish steel plant activity. The start of construction of the new green steel mill, as reported in multiple news articles, does not appear to have any immediate impact on current production activity at the existing facility.

SSAB Oxelösund, another integrated steel plant, relies on BF and BOF processes for its 1,500 ttpa crude steel production. Specializing in high-strength and wear-resistant steels, including Hardox, Strenx, and Armox, the plant has ISO14001 and ResponsibleSteel certifications. The observed activity levels consistently remained the highest among the monitored plants, ranging from 41% to 45%, with no apparent relationship to the news articles or the developments at the Luleå plant.

The news regarding SSAB’s Luleå green steel mill construction, detailed in “Sweden’s SSAB breaks ground for Luleå green steel mill“, “SSAB begins construction of a new plant in Luleå,” “Deputy Prime Minister, SSAB CEO Break Ground on New Steel Mill in Luleå“, “Swedish SSAB is preparing the ground for the construction of an environmentally friendly steel plant in Lulea” and “Construction begins on SSAB’s fossil-free steel mill in Sweden,” does not correlate to observed activity drops.

Given the very positive long-term market outlook coupled with the potential for short-term supply chain adjustments due to the construction activities at SSAB Luleå:

- For steel buyers: Closely monitor SSAB Oxelösund’s production and inventory levels of Hardox and Strenx steels as alternative sources. Diversify suppliers to mitigate risks associated with potential production disruptions during the transition phase at SSAB Luleå.

- For market analysts: Pay close attention to any shifts in SSAB Oxelösund’s production capacity and product mix as the market adapts to the Luleå mill transformation. Track investments in EAF technology across the Swedish steel sector as a leading indicator of the industry’s shift towards green steel production.